Many people often ask me "what is the best-selling product in SUPER DELIVERY?"

Japanese ceramics, of course. So, are you curious about how Japanese ceramics are made?

This time, I came to the production site of Mino ware in Gifu(岐阜県) and Aichi(愛知県). I came to 5 factories that manufacture pottery, to bring you the most realistic Japanese ceramic production process.

Production Method

The process of making pottery: product design → selection of clay → molding → drying → biscuit firing → painting→ to apply glaze → glost firing.

Generally, the design of the product is decided by the designer and the head of the pottery factory after discussion.

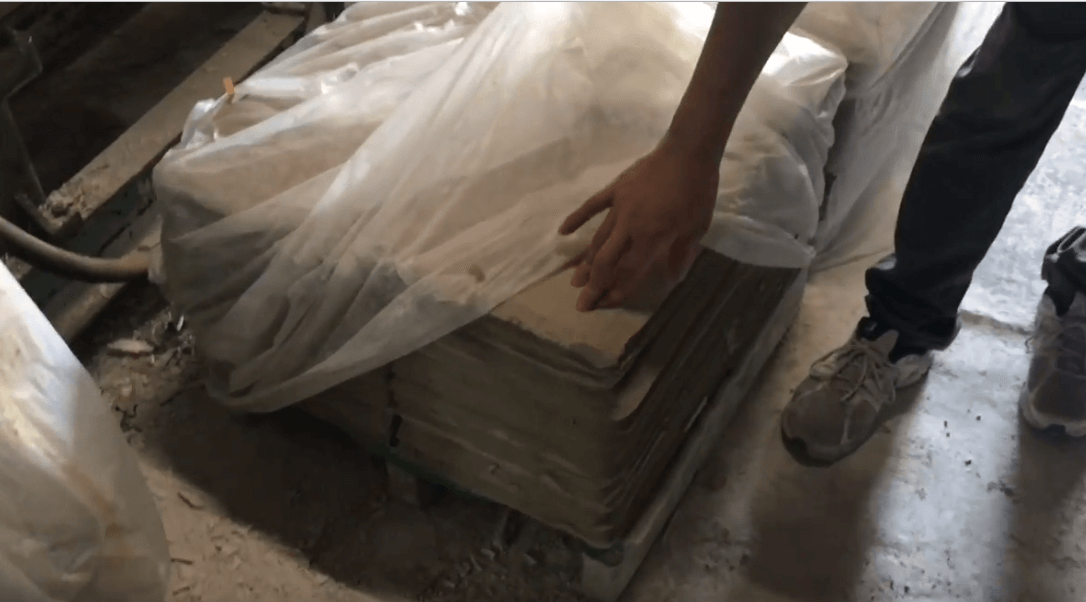

When the product design is decided, the clay will be chosen. Not all soil can be used for making ceramics. According to the demand of different products to choose different soil. Clay is roughly divided into white soil, red soil and black soil.

Molding is the most critical step. This step does not use a lot of the professional props you imagine. Clay, turntable and professional craftsman's technology.

One of the most critical steps to take after forming is drying. If you do not dry or dry not enough, then after biscuit firing will be cracks in the product.

So, what’s the biscuit firing?

If take the dried molded product is glazed directly, the shape will collapse again.

Because the glaze contains moisture, so need the biscuit firing. The biscuit firing is fired at around 800℃ for about 4 hours.

Can the pottery after biscuit firing be used? Of course not. Because the pottery is very absorbent after biscuit firing. Therefore, glazing and glost firing must be carried out. Otherwise, the product will leak.

According to the product different, the glost firing temperature and time are also different. Generally need to burn at 1200-1250℃ for about 12 hours. After the firing is completed, the product will shrink due to long-time high-temperature baking. So in the molding, you have to make a larger size than expected size.

In this way, a pottery is done.

5 factories that manufacture pottery

Minobunzan(美濃文山)

Minobunzan(美濃文山). Because of the need for strict control of the temperature of the product, pottery must be fired indoors. When the kiln was opened, the room reached more than 70℃ in an instant (because the thermometer was unable to measure), very hard. There are 5 employees in this factory. 1500 products can be produced every day.

The CHIPS JAPAN’s product, which sells very well in SUPER DELIVERY, is produced here.

Shibatouen(芝陶苑)

Shibatouen(芝陶苑). This factory has 5 employees. Its products are different from the pottery factory just introduced. They made more porcelain.

The masterpiece has CHIPS mug.

Maruiseitoujyo(マルイ製陶所)

Maruiseitoujyo(マルイ製陶所). The products produced in this factory are mostly porcelain. Most exciting of all, the porcelain sold in Disney is produced here. The production method of the product here is different from the factory described above. The shape of the product here is made out of a mold. The cartoon character is printed on the tableware with a copper plate.

Among their representative works are the Snoopy series of YAMAKA SHOUTEN.

Sabashi Seitojyo(佐橋製陶所)

Sabashi Seitojyo(佐橋製陶所). The products produced in this factory are mainly in the mug cup. There are about 20 employees in the factory. 1 day can produce about 2,500 products. Currently in the production of more than 100 manufacturers of products. Only the mug has more than 100 different kinds. The hardest to make is the complex pattern sticker pottery.

Seitouen(正陶苑)

Seitouen(正陶苑). They are very good at the design of the product. Often study the use of glazes themselves, like the development of new products. There are 5 employees in the factory. 800-1000 products can be produced per day.

One of their most recommended products is this series.

Finally

After a day of understanding in the pottery factory, I feel respect and admiration for this profession from the bottom of my heart. There are few young workers in the 5 pottery factories. I even saw a seventy or eighty-years-old granny.

The person in charge told me that many young people do not want to inherit the pottery factory, do not want to work in the pottery factory. Because they want to go to big cities like Tokyo after they graduate. In addition, they think the job is very hard.

Although I can understand the young people's ideas, but still feel very sad. It is hoped that improvements can be achieved in the future.

At the same time, what we can do is to focus on their works and cherish the fruits of their labor. At the same time, we can only do is what to focus on their work and cherish the fruits of their labor.

What's SUPER DELIVERY?

SUPER DELIVERY is a Japanese largest wholesale e-market place. Import high quality and design products from Japan shortly!